The journey of manufacturing techniques reflects a continuous pursuit of efficiency, quality, and scale. Beginning with basic manual craftsmanship, the industry has experienced transformative periods marked by technological innovations that radically redefine production capabilities.

Introduction

The story of manufacturing is a reflection of human ingenuity, technological progress, and societal transformation. From the earliest days of artisanal craftsmanship to the age of automated factories, this evolution has redefined how goods are produced, distributed, and consumed. Understanding this progression requires examining the multifaceted influences—technological, economic, political, and cultural—that have driven change over centuries.

Background

Origins of Manufacturing

Manufacturing's roots trace back to prehistory, where early humans crafted tools and simple implements. As societies developed, so did techniques for producing goods, evolving from basic handcrafts to more organized forms. The division of labor, specialization, and trade fostered the growth of proto-industrial activities such as weaving, pottery, and metallurgy.

Pre-Industrial Production Techniques

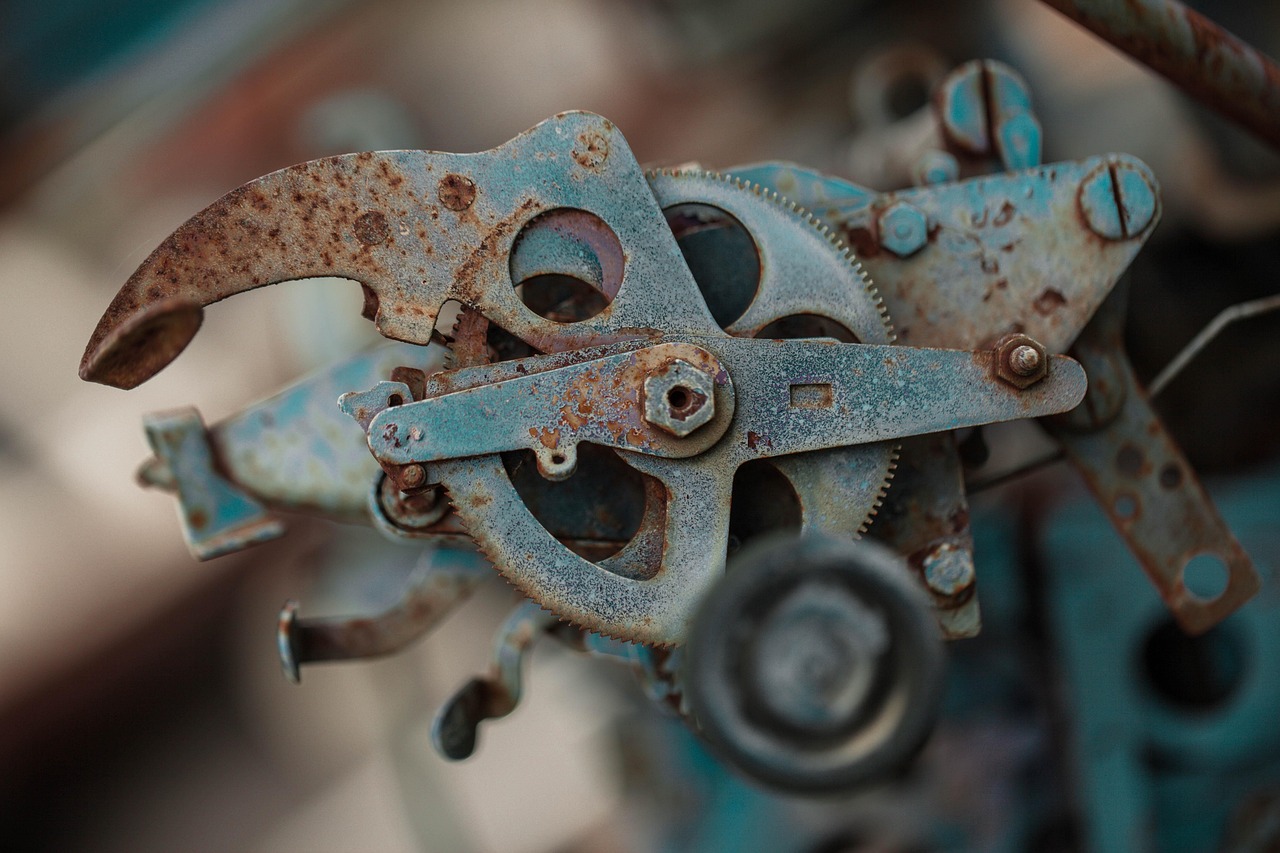

Before the advent of mechanization, production was predominantly manual. Artisans meticulously crafted items in small workshops, often customized and labor-intensive. Techniques like guild systems regulated quality and mastery, ensuring craftsmanship but limiting scale and efficiency. Despite limitations, these practices laid the groundwork for modern manufacturing principles.

Geography

Manufacturing development was geographically uneven, influenced by resource availability, political stability, and technological knowledge transfer. Early centers included regions like the Low Countries and England, which benefitted from waterways, coal deposits, and skilled labor. The Industrial Revolution soon expanded to continental Europe, North America, and beyond, creating a dynamic map of industrial hubs.

Society & Culture

Social Changes Driven by Manufacturing

The shift from manual craftsmanship to mechanized production altered societal structures significantly. The rise of factory work redefined labor patterns, urbanized populations, and created new class distinctions. Mass production reduced costs and made goods more accessible, fueling consumer culture and altering lifestyles.

Workforce Transformations

The factory system introduced regimented work hours, hierarchical management, and division of labor. Child labor and poor working conditions were prominent issues in early factories, igniting social reform movements and labor rights activism, which continue to influence employment practices today.

Economy & Trade

Economic Impacts

Manufacturing advances propelled economic growth through increased productivity, specialization, and technological innovation. The Industrial Revolution catalyzed urbanization and created new markets. Mass production lowered costs, stimulated demand, and expanded trade networks globally.

Trade Networks and Globalization

Enhanced production was paired with expanded trade routes, colonial enterprises, and the rise of global markets. Raw materials were sourced from colonies, while finished goods were exported worldwide, establishing a nascent global economy driven by manufacturing capabilities.

Military & Technology

Military Innovation

The evolution of manufacturing materially impacted military technology. Mass-produced weapons, ships, and equipment enabled rapid military expansion and improved logistics, influencing warfare strategies significantly, as seen in the Napoleonic Wars and later conflicts.

Technological Advancements

Key inventions such as the spinning jenny, power loom, Bessemer converter, and later, assembly lines revolutionized production. These innovations increased efficiency and output, paving the way for continuous improvement and subsequent waves of technological progress.

Governance & Law

Legal frameworks and government policies shaped manufacturing development. Patent laws encouraged innovation, while regulation of labor and safety standards aimed to mitigate social costs. Governments also played vital roles in establishing infrastructure, education, and research institutions to support industry growth.

Archaeology & Sources

Historical artifacts, factory remains, and technological blueprints provide insights into manufacturing's evolution. Archival records, patents, and contemporary writings chronicle shifts in techniques, policies, and societal impacts, serving as indispensable sources for understanding this complex history.

Timeline

- circa 3000 BCE: Early craft production and metallurgy

- Middle Ages: Guild systems and regional trade networks

- 18th century: Mechanical innovations like the spinning jenny

- 1760-1840: The First Industrial Revolution begins in Britain with steam power

- Late 19th century: Second Industrial Revolution, electrification, assembly lines

- 20th century: Automation, robotics, computer-aided manufacturing

Debates & Controversies

Discussions around manufacturing's evolution often focus on labor rights, environmental impact, and technological displacements. The rise of automation sparks debates on job security and income inequality, while historical concerns include exploitation and social neglect during rapid industrialization.

Conclusion

From handcrafted tools to fully automated factories, the journey of manufacturing encapsulates humanity’s relentless pursuit of progress. Each epoch reflects technological mastery, societal change, and economic expansion. As we stand at the cusp of Industry 4.0, understanding this evolution not only honors past innovations but also guides future development in manufacturing’s ongoing saga.