In the age of rapid innovation, the shift from handcrafted methods to mechanized systems marked a seismic change in how goods were produced. Early devices such as the spinning jenny and power loom introduced efficiencies that drastically increased output and decreased reliance on skilled manual labor.

Background

The advent of mechanization marked a pivotal turning point in human history, fundamentally altering traditional modes of production that had persisted for centuries. Prior to this transformation, manufacturing was predominantly manual, reliant on skilled artisans or labor-intensive processes. The Industrial Revolution, originating in late 18th-century Britain and subsequently spreading globally, introduced a paradigm shift: the integration of machinery into the manufacturing landscape. This shift was driven by innovations such as the spinning jenny, water frame, power loom, and the steam engine, which collectively increased productivity, reduced costs, and challenged existing social and economic structures.

Mechanization did not appear suddenly but evolved through a series of technological breakthroughs that built upon earlier developments. The pursuit of efficiency and mass production catalyzed research into more robust and versatile industrial machinery. As these technologies matured, factories transformed from small-scale workshops into centralized hubs of large-scale manufacturing, setting the stage for modern industrial economies.

Geography

The geographical epicenter of mechanized industrial activity was Great Britain, owing to its abundant coal and iron resources, maritime trade networks, and pioneering spirit in engineering. The dissemination of industrial machinery quickly spread to Western Europe, North America, and eventually other parts of the world, adapting to regional resources and labor structures. Key industrial regions such as the Ruhr Valley in Germany, the Northeast United States, and parts of France became focal points for advanced manufacturing systems. The geographic distribution of industries influenced urbanization patterns, with cities expanding rapidly as centers of mechanized production.

Society & Culture

The societal impact of mechanization was profound. Traditional artisan crafts declined as factory work replaced skilled handcrafting, leading to both increased labor specialization and the rise of factory discipline. The working class grew substantially, often subjected to long hours, poor working conditions, and new social dynamics within industrial towns. Concurrently, technological progress fostered a culture of innovation and optimism about human progress, but also provoked societal debates about labor rights, inequality, and the environmental footprint of industrial activity. The mechanization of production gave rise to new social identities centered around industrial labor, influencing cultural norms and educational priorities.

Economy & Trade

The economic landscape was reshaped by mechanized manufacturing. Increased productivity and output lowered production costs, making goods more affordable and accessible. This spurred consumer markets' growth and facilitated international trade expansion. The development of factory-based production systems enabled economies of scale, leading to competitive advantages for industrial nations. Trade networks expanded as mechanized goods, and raw materials flowed globally, fostering interconnected markets and catalyzing economic globalization. Wealth accumulation within industrial centers concentrated capital investment in technology and infrastructure, accelerating economic growth.

Military & Technology

Mechanization also transformed military technology, with innovations in weaponry, transportation, and logistics. Steam-powered ships and railways enhanced mobility, enabling rapid deployments and resource movement. The industrial machinery used for civilian purposes often had dual applications, leading to the development of materials and techniques that improved military capabilities. This technological progress contributed to the emergence of new warfare strategies and geopolitical power shifts, embedding industrial strength into national security frameworks.

Governance & Law

The rise of mechanized industry prompted legislative responses addressing labor rights, safety regulations, and intellectual property rights. Governments faced pressure to regulate factory working conditions, enforce standards, and manage the social consequences of rapid economic change. Legal frameworks evolved to balance industrial growth with societal well-being—epitomized by legislation such as factory acts and patent laws. Politically, industrialization influenced policymaking, with shifts toward supporting infrastructure development, education, and social reforms aimed at integrating industrial workers into the fabric of emerging modern states.

Archaeology & Sources

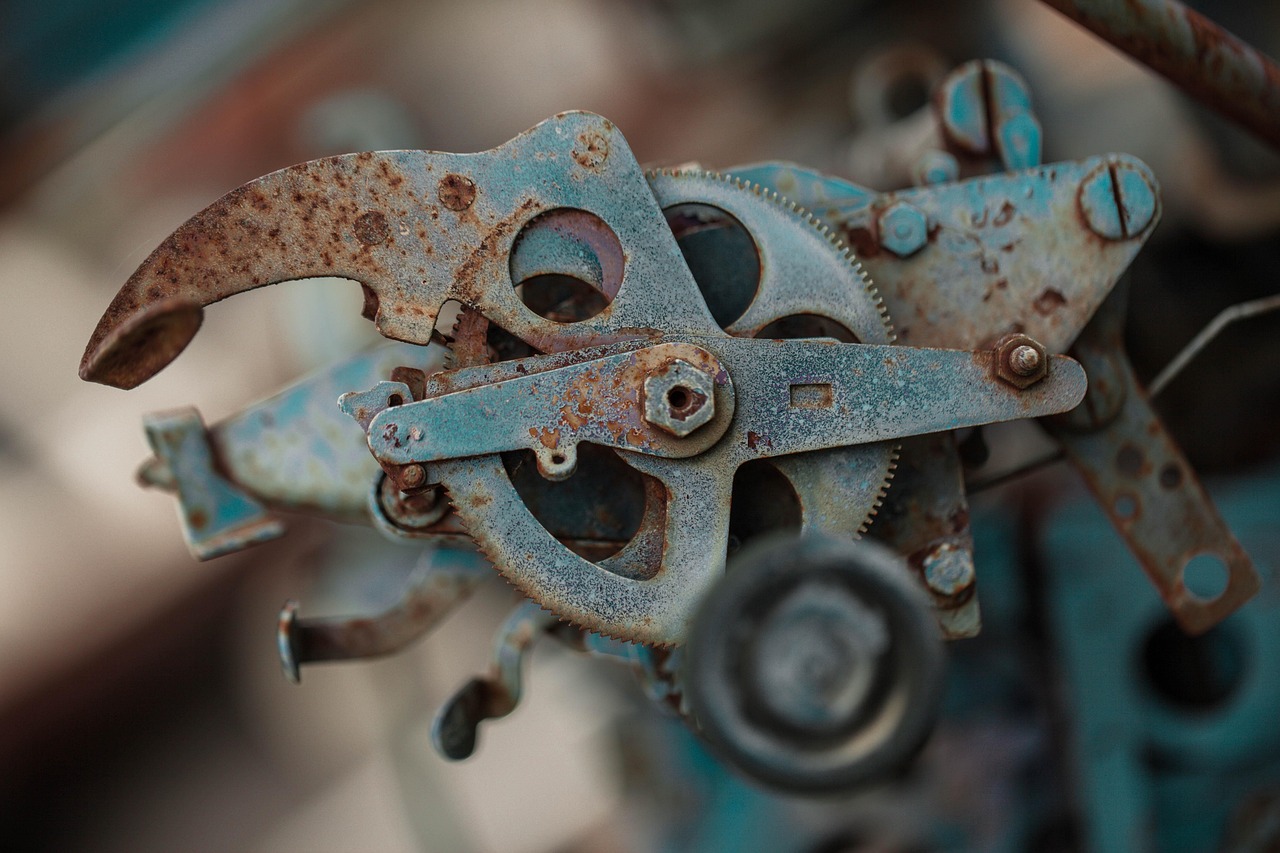

Archaeological investigations, including factory ruins, machinery remnants, and urban infrastructure, offer tangible insights into the scale and sophistication of early mechanized industries. Primary sources such as factory records, engineering blueprints, patent documents, and contemporary correspondences reveal technological details and business dynamics. Historians also rely on visual art, photographs, and oral histories to reconstruct the social impact of mechanization phases and regional variations in industrial practice.

Timeline

- 1764 - Invention of the spinning jenny by James Hargreaves

- 1769 - James Watt improves the steam engine

- 1779 - Crompton's water frame enhances spinning machinery

- 1785 - Power loom patent by Edmund Cartwright

- 1825 - Opening of the Stockton and Darlington Railway

- 1830 - First public demonstration of the electric telegraph

- 1856 - Bessemer process revolutionizes steel production

- 1876 - Alexander Graham Bell invents the telephone

- 1908 - Ford introduces assembly line production

Debates & Controversies

Mechanization spurred considerable debate regarding its social and economic effects. Critics argued that industrial automation displaced skilled artisans, degraded working conditions, and entrenched economic inequality. Others highlighted the environmental degradation resulting from coal usage and waste from factories. Debates over intellectual property rights and technological monopolies emerged as powerful entities sought to control industrial innovations. The question of technological determinism—whether machinery inevitably shapes society—remains a central theme in historical discussions about industrial change.

Conclusion

The mechanization of manufacturing processes during the Industrial Revolution represents a defining chapter in human history, illustrating how technological ingenuity catalyzed profound social, economic, and political changes. From humble beginnings with simple machinery to complex production systems, this evolution exemplifies the transformative power of innovation. Today’s advanced automation and robotics are extensions of this legacy, ensuring that the story of mechanized workflows remains pivotal in imagining the future of industry and society.