The dawn of the Industrial Revolution marked a period of profound change in how goods were produced. Innovations in machinery, energy use, and process management forged a new landscape for manufacturing, setting the stage for modern economic development.

Background

The evolution of manufacturing technology has been a defining feature of human progress, with the Industrial Revolution serving as a watershed moment that inaugurated an era of unprecedented industrial growth and societal transformation. Rooted in innovations that enhanced productivity and enabled mass production, these technological advancements laid the foundation for modern manufacturing ecosystems. The shift from craft-based, manual production to mechanized and automated systems facilitated larger-scale outputs, efficiency, and the emergence of new economic paradigms. Understanding this historical backdrop provides essential context for appreciating the magnitude and implications of current manufacturing technologies.

Geography

The geographical distribution of early industrial activity was heavily influenced by access to raw materials, navigable waterways, and proximity to coal and iron deposits. Western Europe, particularly Britain, was at the forefront owing to its rich resources and favorable climate for innovation. The clustering of textile mills, ironworks, and machinery factories along river valleys exemplifies how geography facilitated industrial growth. Over time, technological developments, such as railroads and telegraphs, expanded the geographical reach of manufacturing, enabling global supply chains and industrial hubs across North America, Europe, and Asia. Today, the digital revolution has transcended physical geography, with virtual manufacturing networks and smart factories playing pivotal roles worldwide.

Society & Culture

The societal implications of manufacturing innovations are profound. The rise of factories led to urbanization, shifts in labor practices, and changes in social stratification. Workers adapted to shift-based work, and new classes emerged, including industrial capitalists and a burgeoning working class. Cultural perceptions of work, efficiency, and mechanization evolved, influencing societal values and behaviors. Moreover, technological advancements fostered a culture of innovation, research, and education, which continues to drive progress today. The interplay between technological change and societal adaptation underscores the complex relationship between manufacturing and human development.

Economy & Trade

Manufacturing technological innovations have been central to economic growth and global trade dynamics. The Industrial Revolution enabled economies of scale, reduced production costs, and allowed for the mass export of goods. This led to the expansion of international markets, the establishment of colonial trade networks, and the emergence of multinational corporations. The increase in manufactured goods also stimulated demand for raw materials, transportation infrastructure, and financial services. In modern times, advancements such as automation, digital twins, and additive manufacturing continue to reshape economic structures, fostering just-in-time production, customization, and supply chain resilience.

Military & Technology

Many manufacturing innovations originated or were accelerated by military needs, especially during wartime. The development of precision machinery, metallurgy, and chemical processes found dual-use applications in defense industries. The technological race during the World Wars, including radar, jet engines, and early computers, spurred further industrial research and expansion. Today, military technology remains intertwined with manufacturing innovation, driving advancements in materials science, robotics, and cybersecurity—a symbiotic relationship that continually pushes the boundaries of industrial capabilities.

Governance & Law

Legal and institutional frameworks have both shaped and been shaped by manufacturing innovation. Patents, intellectual property laws, and trade regulations have protected innovations, incentivizing investment. Governments have historically supported industrial growth through policies, subsidies, and infrastructure projects. Regulatory bodies address safety, environmental impact, and labor standards, balancing technological progress with societal needs. Contemporary issues include managing technological disruptions, cybersecurity, and sustainable manufacturing practices that comply with evolving legal standards.

Archaeology & Sources

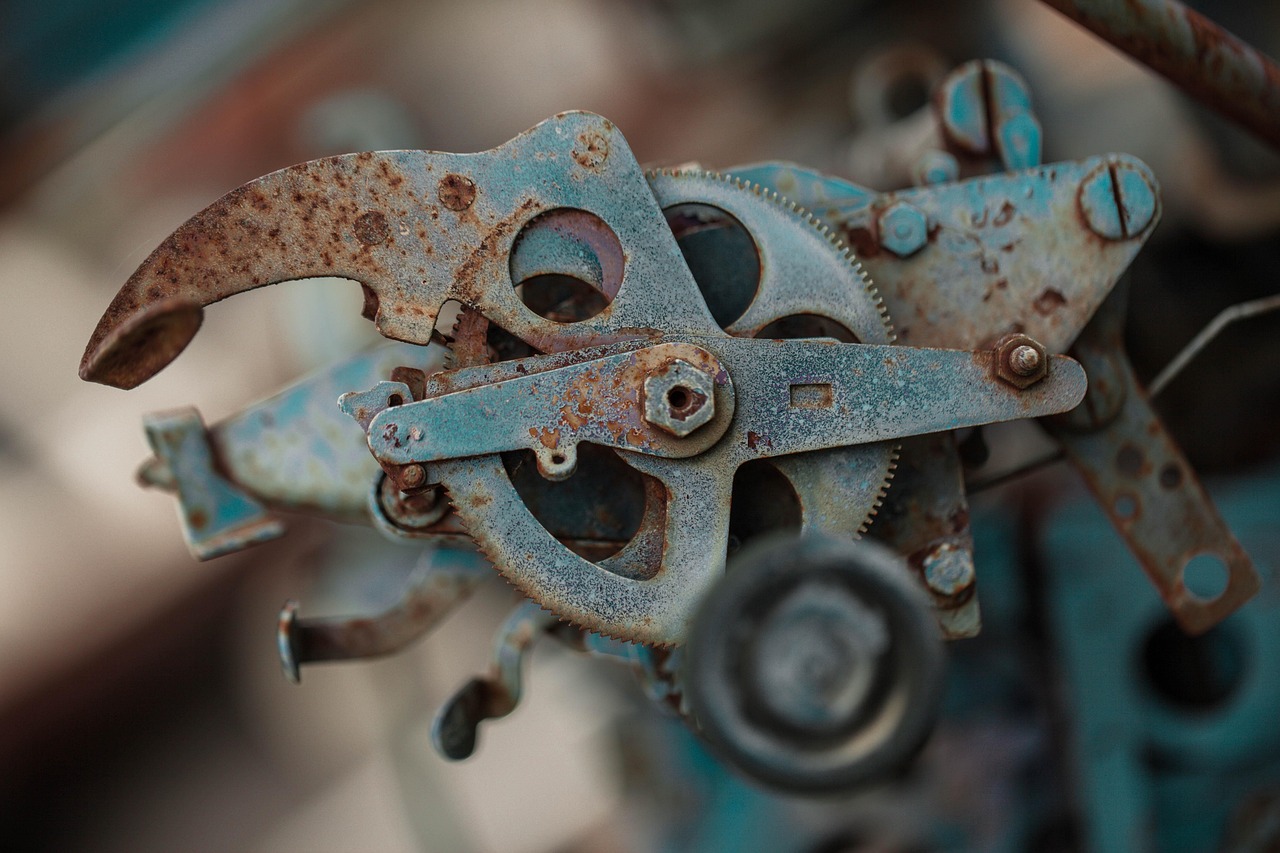

Archaeological studies of industrial sites, machinery remnants, and early factory layouts shed light on the technological evolution of manufacturing. Archives, patent records, and manufacturing manuals offer documentary evidence of innovations and operational practices. These sources help trace the diffusion of key technologies and understand the socio-economic context of different eras. The preservation and analysis of industrial heritage continue to inform contemporary debates around innovation and sustainability.

Timeline

- 1764 - Invention of the Spinning Jenny

- 1779 - Watt's steam engine improvements \li>1793 - Cotton gin patent

- 1825 - Opening of the Stockton and Darlington Railway

- 1870 - Bessemer process for steel production

- 1908 - Introduction of assembly line by Henry Ford

- 1950s - Adoption of early computer numerical control (CNC) machines

- 1970s - Rise of CAD/CAM technologies

- 2000s - Adoption of digital manufacturing and Industry 4.0

- 2020s - Integration of AI, IoT, and robotics in manufacturing

Debates/Controversies

Key debates revolve around automation versus employment, environmental impact, and intellectual property rights. The displacement of manual labor by robotics raises questions about job security and economic inequality. The environmental footprint of manufacturing, especially with the increasing use of energy-intensive technologies, prompts discussions on sustainability. Intellectual property laws, especially in the digital age, influence innovation diffusion and access. Ethical considerations also emerge with emerging technologies like AI-driven robots and genetic manufacturing methods.

Conclusion

From the mechanization of textile production to the dawn of Industry 4.0, technological inventions have been central to shaping the manufacturing landscape. These innovations have driven economic growth, societal change, and military strength, while raising important debates about their future trajectory. Continual evolution in manufacturing technology promises to forge new pathways for industrial growth, emphasizing the need for adaptive policies, sustainable practices, and a forward-looking perspective on technological progress.