Before the advent of the refined steam engine, human industry was largely tethered to the whims of nature. Waterwheels harnessed rivers, windmills relied on breezes, and muscle power – both human and animal – was the primary engine for most tasks. This limited the scale and location of manufacturing, tying burgeoning industries to specific geographical constraints. Mines, in particular, struggled with flooding, requiring constant, arduous pumping to extract precious minerals.

The dawn of the Industrial Revolution was heralded not by a thunderclap, but by the rhythmic hiss and thud of a machine that would forever alter the course of human civilization: the steam engine. While Thomas Newcomen had laid the groundwork with his pioneering atmospheric engine in the early 18th century, it was the genius of James Watt, a Scottish instrument maker, that truly unleashed the transformative power of steam. His seemingly modest refinements, particularly the invention of the separate condenser, dramatically enhanced efficiency and versatility, transforming a cumbersome water-pumping device into the prime mover of global industry. What some might have initially dismissed as 'Watt's Folly' ultimately became the bedrock upon which modern industrial society was built, igniting an era of unprecedented technological innovation and societal change.

Overview: The Genesis of Industrial Power

Before Watt, the Newcomen atmospheric engine, while revolutionary for its time, was a thirsty beast, consuming vast quantities of coal to power its laborious strokes. Primarily employed for draining water from deep mines, its operational limitations hindered widespread adoption. James Watt, tasked with repairing a Newcomen engine model in 1763, was struck by its inherent inefficiency. His subsequent investigations and inventive leaps led to a series of patented improvements, most notably the separate condenser, which drastically reduced fuel consumption and opened the door for steam power to be applied to a myriad of industrial processes. The partnership with entrepreneur Matthew Boulton provided the crucial capital and business acumen, propelling the Boulton & Watt firm to the forefront of the burgeoning industrial landscape and cementing the steam engine's role as the engine of the Industrial Revolution.

Principles & Laws: Harnessing Heat for Work

Thermodynamic Fundamentals

At its heart, the steam engine operates on fundamental thermodynamic principles, converting heat energy into mechanical work. The key lies in the properties of steam and the creation of a vacuum. Water, when heated sufficiently, turns into steam, a gaseous form that occupies a much larger volume than its liquid counterpart and exerts considerable pressure. When this steam is then cooled, it condenses back into water, dramatically reducing its volume and creating a partial vacuum. The atmospheric pressure acting on one side of a piston, coupled with this vacuum on the other, creates a powerful differential force.

The Inefficiency of Newcomen

The Newcomen engine suffered from a critical thermodynamic flaw: its single cylinder served as both the working chamber and the condensing chamber. After the power stroke, a jet of cold water was injected directly into the hot cylinder to condense the steam and create the vacuum. This process cooled the cylinder walls significantly. In the subsequent stroke, fresh, hot steam entered the now-cooled cylinder, losing a substantial amount of its latent heat (the energy required to change water into steam) simply reheating the cylinder walls. This repeated heating and cooling of the cylinder represented a massive waste of energy, making the engine incredibly inefficient and costly to run.

Watt's Insight: The Separate Condenser

Watt's genius lay in recognizing this fundamental inefficiency. His groundbreaking insight was to separate the condensing process from the power cylinder. By connecting the main cylinder to a separate, evacuated vessel (the condenser) via a valve, steam could be drawn into this cold chamber to condense, leaving the main cylinder hot and ready for the next charge of fresh steam. This innovation dramatically reduced heat loss, making the engine far more fuel-efficient.

Methods & Experiments: From Concept to Commercial Success

Early Observations and Iterations

Watt's initial 'Aha!' moment occurred during a Sunday walk in Glasgow Green in 1765, where the concept of the separate condenser crystallized. He realized that if the steam could be condensed in a vessel distinct from the cylinder, the cylinder could be kept hot, thus saving the immense amount of heat lost in reheating it with each cycle. His early experiments involved various forms of condensers, often using pumps to maintain a partial vacuum and extract the condensed water.

Beyond the Condenser: Further Refinements

While the separate condenser was Watt's most impactful invention, his work didn't stop there. He introduced several other crucial improvements:

- Steam Jacketing: To further minimize heat loss, Watt surrounded the working cylinder with a jacket filled with live steam. This kept the cylinder walls at a consistently high temperature, preventing condensation within the cylinder itself.

- Air Pump: To ensure the highest possible vacuum, Watt incorporated an air pump to remove condensed water and non-condensable gases from the condenser.

- Double-Acting Engine: By introducing steam alternately to both sides of the piston, Watt created a double-acting engine, producing power on both the up and down strokes. This made the engine smoother, more powerful, and enabled continuous rotary motion.

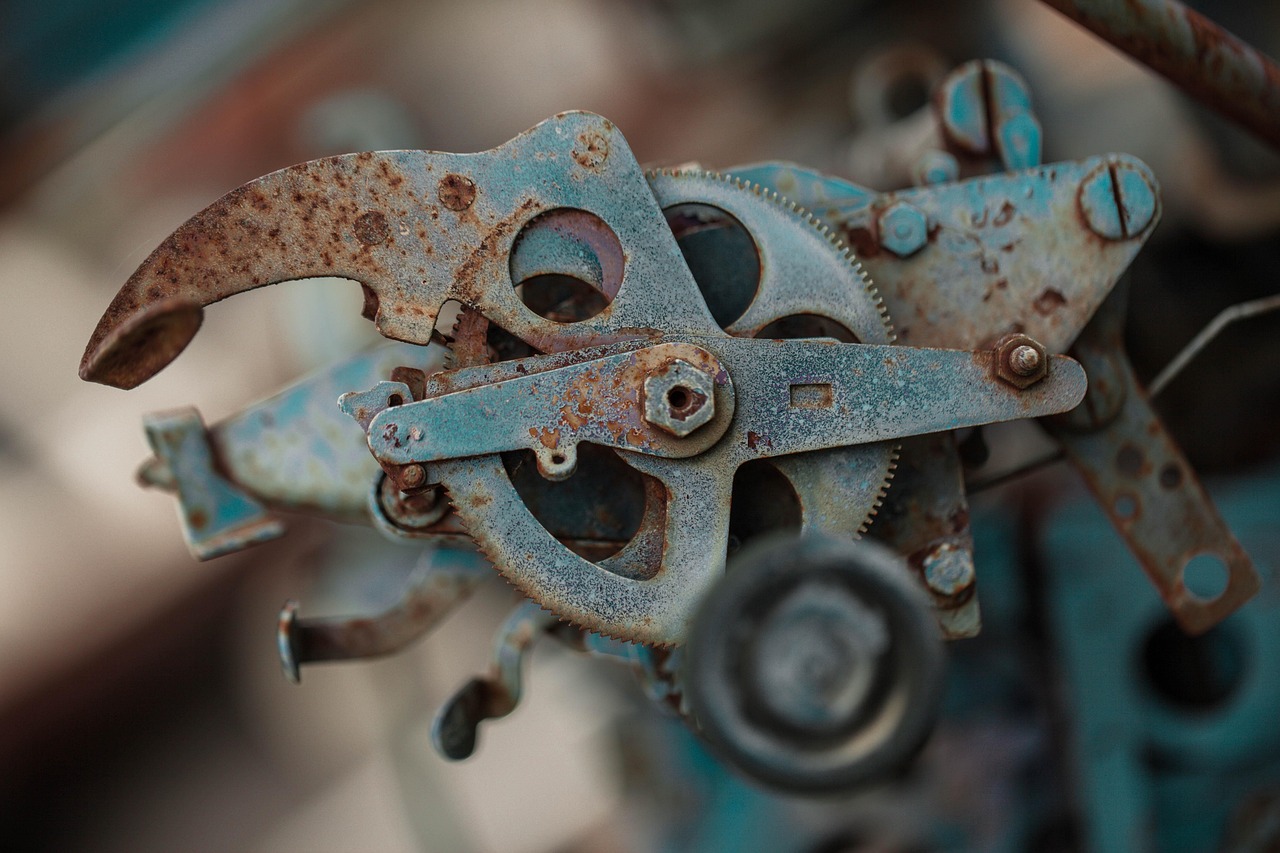

- Parallel Motion Linkage: To guide the piston rod in a perfectly straight line, Watt invented the 'parallel motion' linkage, an ingenious mechanical solution that replaced less stable chains.

- Sun-and-Planet Gear: Originally, Watt intended to use a crank for converting reciprocating motion into rotary motion. However, James Pickard patented the crank first. Watt cleverly circumvented this by inventing the sun-and-planet gear, allowing the engine to drive rotating machinery in factories and mills, a critical step for industrial applications beyond pumping.

Data & Results: Quantifying Efficiency and Power

The impact of Watt's innovations was staggering. Compared to the Newcomen engine, Watt's engines typically reduced fuel consumption by 75%, making them far more economical to operate. This efficiency gain was revolutionary, especially in an era where coal was the primary energy source. The Boulton & Watt company often charged its customers based on the savings in fuel costs, a testament to the quantifiable improvement their engines offered. This 'engine duty' system allowed for rapid capitalization and further investment in innovation.

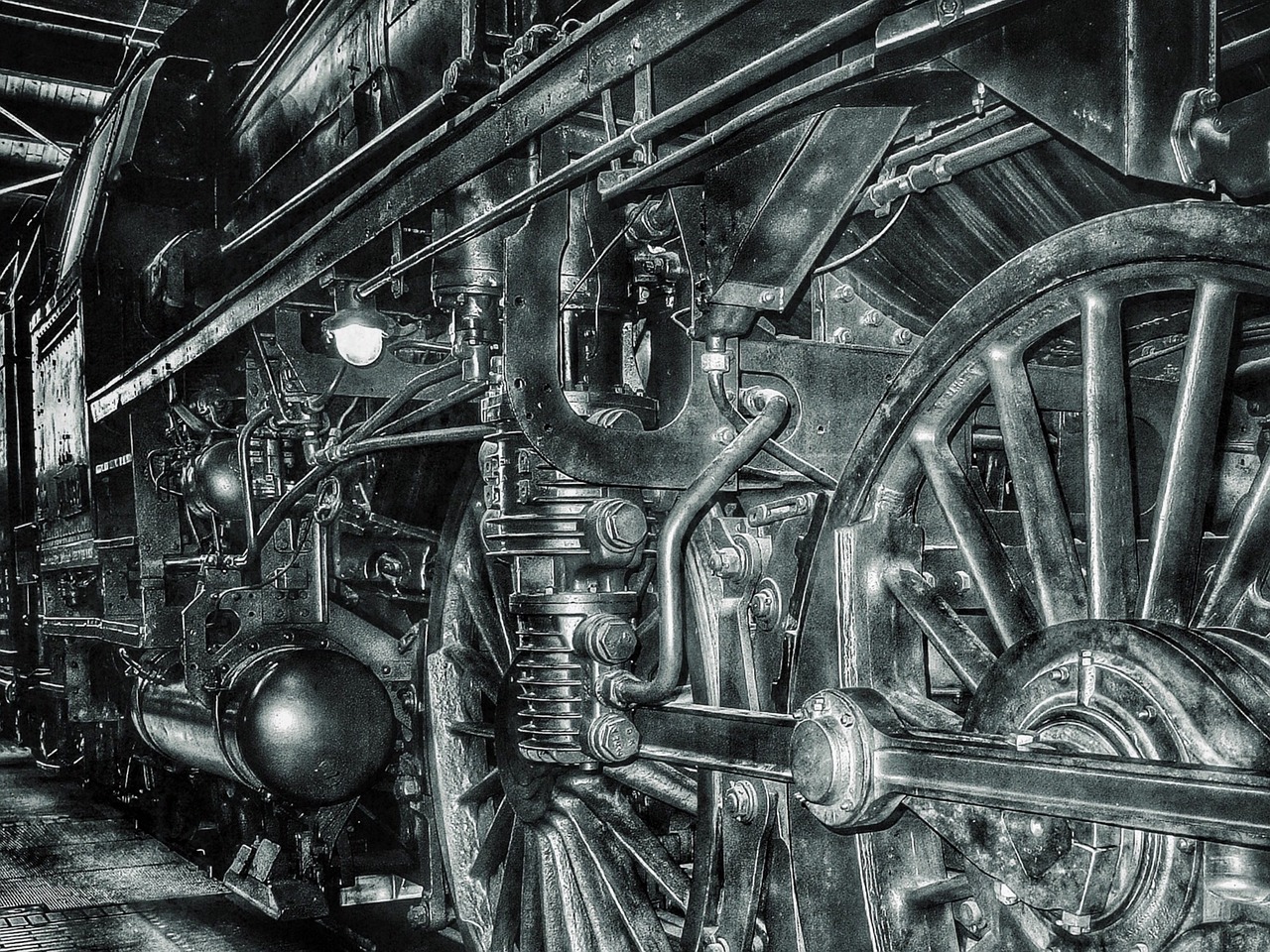

Furthermore, the double-acting engine combined with the sun-and-planet gear provided a continuous, smooth rotary motion, which was essential for driving factory machinery. The power output, measured in 'horsepower' (a term coined by Watt himself to market his engines, comparing them to the output of horses), was significantly higher and more consistent, allowing for the centralization of production in factories rather than dispersed workshops relying on water or wind power.

Applications & Innovations: Fueling the Revolution

From Mines to Mills

Initially, Watt's engines found their primary application in pumping water out of mines, particularly coal and tin mines in Cornwall. Their superior efficiency meant deeper mines could be worked profitably. However, it was the development of the rotary motion engine that truly unleashed the Industrial Revolution. By connecting steam engines to drive shafts, they could power textile mills, flour mills, breweries, and ironworks. This independence from rivers (for water wheels) or unpredictable winds allowed factories to be built anywhere, leading to unprecedented urban growth and the concentration of industry.

Expanding Horizons

The success of the stationary steam engine paved the way for its adaptation into mobile applications. While Watt himself was skeptical of high-pressure engines suitable for locomotion, his fundamental designs and principles were essential for later pioneers like Richard Trevithick and George Stephenson, who developed steam locomotives and steamboats, further revolutionizing transportation and trade across land and sea.

Key Figures: Minds Behind the Machines

- James Watt (1736-1819): The central figure, an instrument maker and engineer whose intellectual curiosity and persistent experimentation led to the pivotal innovations in steam engine design. His understanding of latent heat and thermal efficiency was revolutionary.

- Matthew Boulton (1728-1809): Watt's astute business partner. Boulton, a successful manufacturer from Birmingham, provided the financial backing, manufacturing facilities (Soho Manufactory), and commercial drive that transformed Watt's inventions from prototypes into a global industrial force. Their partnership, Boulton & Watt, became synonymous with industrial progress.

- Thomas Newcomen (1664-1729): The inventor of the first practical atmospheric steam engine (c. 1712). While less efficient, Newcomen's engine provided the essential groundwork and proof-of-concept for harnessing steam power, making Watt's subsequent improvements possible.

- John Smeaton (1724-1792): A prominent civil engineer of the era who rigorously studied and improved the Newcomen engine, providing valuable data that may have influenced Watt's understanding of its inefficiencies.

Ethical & Societal Impact: A Double-Edged Sword

The widespread adoption of Watt's steam engine brought about unprecedented economic growth and societal transformation. Factories, powered by steam, could produce goods on an unimaginable scale, leading to cheaper products and a greater variety of consumer goods. Urbanization exploded as people moved from rural areas to factory towns in search of work. New social classes emerged, and Great Britain ascended to become the world's leading industrial power.

However, this progress came at a significant cost. The factory system often subjected workers to deplorable conditions: long hours, dangerous machinery, low wages, and the widespread use of child labor. Industrial pollution fouled air and water, creating unhealthy living environments in rapidly growing cities. The displacement of traditional agrarian and craft economies led to social upheaval, protests, and a widening gap between the wealthy industrialists and the working class. Watt's engine, while a marvel of engineering, was a tool that amplified both the potential for prosperity and the capacity for exploitation.

Future Directions: Lessons from the Past

The story of Watt's steam engine is a powerful narrative of technological innovation driving societal change. As humanity grapples with the transition to sustainable energy sources and faces the challenges of climate change, the lessons from the Industrial Revolution are more pertinent than ever. The drive for efficiency, the ingenuity in harnessing new forms of energy, and the careful consideration of the broader societal and environmental impacts are all themes that echo from Watt's era into our own. The ongoing quest for cleaner, more efficient power generation continues to build upon the thermodynamic foundations laid by pioneers like James Watt, albeit with vastly different technologies.

Conclusion: The Engine That Forged a World

James Watt's refinement of the steam engine was far more than a mere mechanical improvement; it was a catalyst for an entirely new world order. His separate condenser, double-acting engine, and rotary motion capabilities transformed an inefficient pump into the versatile prime mover that defined the First Industrial Revolution. From draining mines to powering textile looms, the Boulton & Watt engine enabled unprecedented levels of production, urbanization, and economic expansion. While its advent brought both immense progress and profound social challenges, there's no denying that Watt's 'folly' was, in fact, an act of genius that laid the indelible foundations for modern industrial society, forever changing how humans work, live, and interact with their environment.