In the grand tapestry of human innovation, some threads, though foundational, often fade into the background. One such thread is James Watt's centrifugal governor – a device so simple in appearance, yet so profound in its impact, it can rightly be called the forgotten algorithm that stabilized the Industrial Revolution.

Introduction to Industrial Revolution

In the annals of technological advancement, certain innovations stand as silent sentinels, their profound impact often overshadowed by more visibly dramatic inventions. Among these is James Watt's centrifugal governor, a marvel of mechanical ingenuity that, while seemingly simple, provided the crucial stability needed to unleash the full potential of the steam engine and, by extension, the entire Industrial Revolution. It was more than just a piece of machinery; it was the practical embodiment of the world's first widely adopted automatic feedback control system, a concept so fundamental it underpins nearly every automated process today.

Overview

The dawn of the Industrial Revolution was marked by a relentless drive for power, and James Watt's improved steam engine provided it in abundance. However, raw power alone was insufficient. Early steam engines, particularly before Watt's governor, were notoriously inconsistent. Their speed would fluctuate wildly depending on the load, making them difficult to integrate with machinery that required precise, consistent motion, such as textile looms, grinding mills, or lathes. Imagine a factory floor where every machine sped up and slowed down unpredictably – productivity would plummet, product quality would suffer, and mechanical failures would be rampant.

The Genesis of a Problem

Before Watt's innovation, controlling the speed of a steam engine was largely a manual affair. An operator would constantly monitor the engine's speed and manually adjust the steam throttle valve to maintain a desired rpm. This was a tedious, imprecise, and labor-intensive task, prone to human error and incapable of reacting swiftly to sudden changes in load. The result was an engine that was powerful but unruly, a beast yet to be tamed. This instability was a significant bottleneck, preventing the steam engine from reaching its true potential as a reliable, scalable power source for burgeoning industries.

Watt's Ingenious Solution

Enter James Watt, whose genius extended beyond mere improvements in thermal efficiency. In 1788, he patented his centrifugal governor, a device designed to automatically regulate the speed of his steam engines. The governor was a brilliant solution to a pervasive problem, translating the engine's current speed into a mechanical input that controlled its future speed. It was, in essence, an early form of mechanical intelligence, a self-correcting mechanism that brought order to industrial chaos and cemented Watt's legacy not just as an inventor, but as a foundational figure in automation history.

Principles & Laws

The elegance of Watt's governor lies in its direct application of fundamental physical principles, primarily centrifugal force and the then-nascent concept of negative feedback control.

Centrifugal Force and Rotational Dynamics

At the heart of the governor's operation is the principle of centrifugal force. The device typically consists of two heavy metal balls, or 'flyballs', suspended by rigid arms from a vertical spindle. This spindle is mechanically linked to the engine's crankshaft, causing it to rotate proportionally to the engine's speed. As the engine speeds up, the spindle spins faster, increasing the centrifugal force acting on the flyballs. This force pulls the balls outwards and upwards against the force of gravity, causing the arms to pivot and lift a sliding collar on the spindle.

Feedback Control Systems: A Nascent Concept

The movement of the sliding collar is the genius of the feedback loop. The collar is mechanically connected to a lever system that, in turn, operates the engine's main steam throttle valve. When the engine speed increases, the flyballs rise, the collar lifts, and the steam valve begins to close, reducing the flow of steam to the engine's cylinders. Conversely, if the engine speed drops (due to an increased load, for example), the centrifugal force on the flyballs decreases, they fall inwards and downwards, the collar lowers, and the steam valve opens wider, allowing more steam to enter and accelerating the engine. This continuous, self-regulating process is a classic example of a negative feedback control system, where the output (engine speed) is constantly monitored and used to adjust the input (steam flow) to maintain a desired set point.

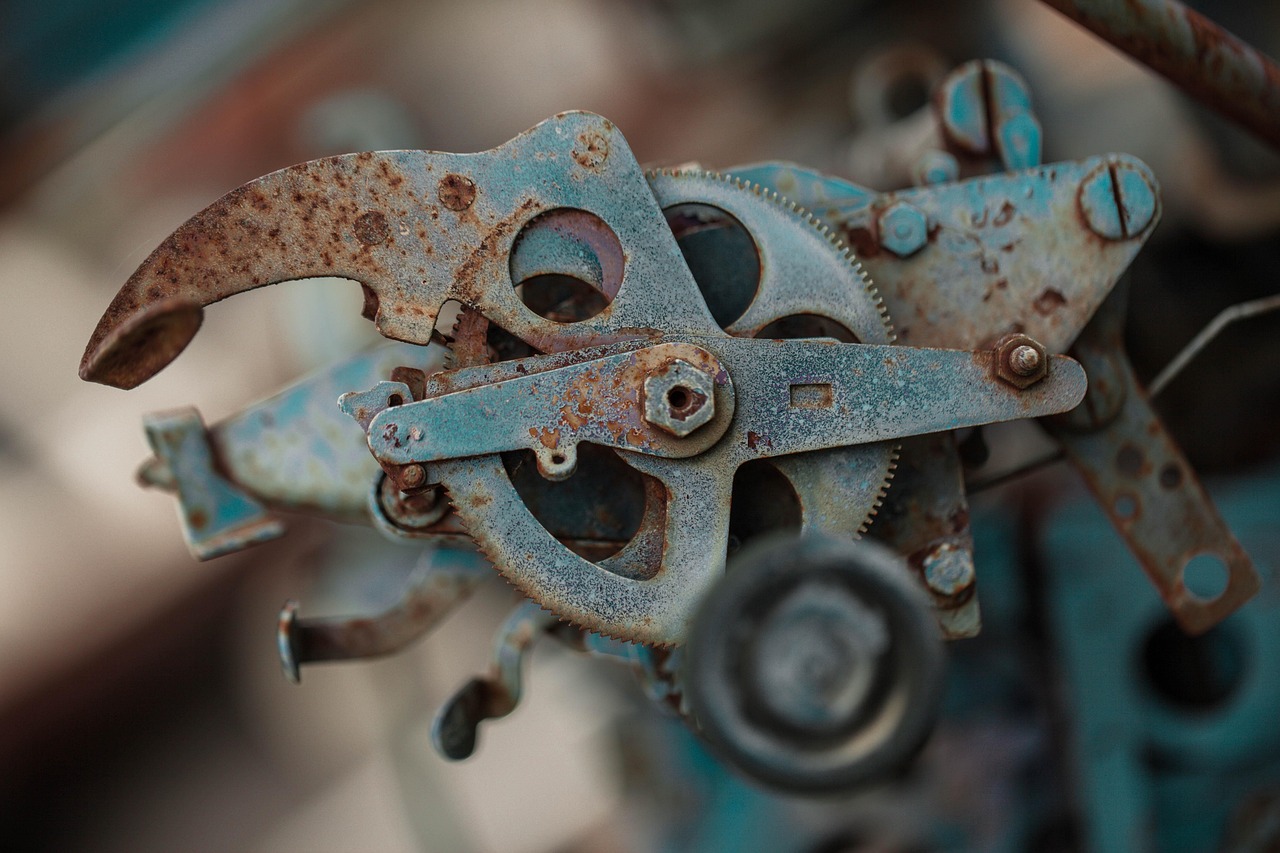

The Governor's Mechanism: A Detailed Look

The governor's typical configuration involved a vertical shaft driven by a belt or gear from the engine's flywheel or crankshaft. Two arms, each bearing a heavy brass or cast iron ball, were hinged to this shaft or a sleeve on it. As the shaft rotated, the balls swung outwards. The linkage between the ball arms and the steam valve was critical. It was often a simple lever system: the rising and falling of the balls translated into a linear vertical motion of a sleeve, which then actuated a 'butterfly' valve or a 'throttle' valve, controlling the steam supply. The weight of the balls, the length of the arms, and the gearing ratio from the engine all contributed to the governor's sensitivity and the 'set point' at which it would maintain the engine's speed.

Methods & Experiments

Watt's governor was not born fully formed; it was the product of empirical observation, iterative design, and practical application, hallmarks of the early mechanical engineering discipline.

Empirical Development and Iteration

Watt's initial attempts at speed regulation were simpler, often involving manual adjustments or less sophisticated mechanisms. The idea of using centrifugal force for regulation was not entirely new, with some prior rudimentary designs existing for windmills. However, Watt's genius lay in adapting this principle specifically to the steam engine's unique challenges and integrating it into a robust, reliable, and practically effective system. His development process involved building prototypes, observing their behavior under varying engine loads, and refining the geometry and mass of the components to achieve optimal stability and responsiveness.

Integration with the Steam Engine

The successful integration of the governor required meticulous mechanical design. The connection to the engine's crankshaft had to be reliable, often employing belts or gear trains to ensure precise proportionality between engine speed and governor speed. The linkage to the steam valve had to be engineered to operate smoothly, without excessive friction or play, which could introduce 'hunting' (oscillations around the desired speed) or sluggishness. Watt and his partner Matthew Boulton were masters of practical engineering, understanding that an invention was only as good as its manufacturability and durability in the harsh industrial environment.

The Role of Observation and Calibration

Early governors required careful calibration for each engine and application. Factors like the desired operating speed, the range of expected load variations, and the engine's inherent responsiveness had to be considered. This calibration often involved trial and error, adjusting the weights of the balls, the pivot points, and the linkage ratios until the engine maintained a steady speed under typical operating conditions. This empirical approach, while lacking the rigorous mathematical models of later control theory, was highly effective and demonstrated a deep intuitive understanding of dynamic systems.

Data & Results

The introduction of Watt's governor yielded immediate and profound improvements, transforming the operational landscape of factories and mills.

Stabilized Speed and Enhanced Efficiency

The most direct result was the unprecedented stability of engine speed. Factories powered by governor-equipped steam engines could now operate machinery at a consistent pace, regardless of minor fluctuations in load. This consistency translated directly into higher quality products, especially in textile manufacturing where uneven yarn or cloth could be produced by erratic power. It also improved the efficiency of the engine itself, as it could operate closer to its optimal performance parameters without constant manual intervention, saving fuel and reducing wear and tear.

Increased Reliability and Safety

A stable engine was a more reliable engine. Reduced speed fluctuations meant less stress on mechanical components, leading to fewer breakdowns and lower maintenance costs. Furthermore, by preventing the engine from 'running away' (overspeeding catastrophically under light load), the governor significantly enhanced safety, protecting both machinery and human operators from potential accidents.

Paving the Way for Industrial Scale-Up

Perhaps the most significant, albeit indirect, result was the enablement of large-scale industrialization. With reliable and consistent power, factories could grow in size and complexity. The governor made it feasible to connect multiple machines to a single engine via complex shafting systems, turning scattered workshops into integrated, efficient production units. It allowed for greater specialization of labor and higher output, fundamentally restructuring economic activity.

Applications & Innovations

The governor's immediate application was to Watt's rotative steam engine, but its conceptual influence stretched far beyond.

Industrial Revolution Powerhouse

By stabilizing the steam engine, the governor unlocked its potential as the primary power source for the Industrial Revolution. It made possible the efficient operation of cotton mills, flour mills, ironworks, and later, the pumping stations and early locomotives. Without the governor, the widespread adoption of steam power and the subsequent factory system would have been severely hampered. It was the crucial link between raw power and productive utility.

Influence on Subsequent Control Systems

The Watt governor became the paradigmatic example of an automatic control system for well over a century. Its success inspired generations of engineers and scientists to explore similar feedback mechanisms in other contexts. While the mathematical theory of control would not fully emerge until the late 19th and early 20th centuries (with figures like James Clerk Maxwell offering the first rigorous analysis of the governor's stability in 1868), Watt's device provided the practical proof of concept. It demonstrated that a machine could sense its own state and adjust its behavior accordingly, a revolutionary idea.

From Steam to Modern Control

The legacy of the Watt governor is evident in virtually every modern control system, from the cruise control in your car to the sophisticated PID (Proportional-Integral-Derivative) controllers found in industrial automation. The principles of sensing a deviation from a set point and applying a corrective action through a feedback loop remain fundamental. It represents the very first step in humanity's quest to build machines that can regulate themselves, a journey that continues with today's advanced robotics and artificial intelligence.

Key Figures

The story of the governor is inextricably linked to the towering figures of the early Industrial Revolution.

James Watt: The Visionary Engineer

James Watt (1736–1819) was a Scottish inventor and mechanical engineer whose improvements to the Newcomen steam engine were fundamental to the changes brought by the Industrial Revolution. His separate condenser dramatically improved the engine's efficiency, but it was his comprehensive approach to the entire system, including the centrifugal governor, that truly solidified his impact. Watt possessed a profound understanding of mechanics and a relentless drive to solve practical problems, making him one of history's most influential engineers.

Matthew Boulton: The Industrial Partner

Watt's collaboration with the industrialist Matthew Boulton was crucial. Boulton provided the financial capital, manufacturing expertise, and business acumen necessary to develop, produce, and market Watt's innovations. Their Soho Manufactory became a hub of industrial innovation, bringing Watt's designs, including the governor, to widespread commercial success. Boulton understood that a brilliant invention needed robust industrialization to change the world.

Early Theorists and Later Developments

While Watt invented the governor empirically, its theoretical understanding evolved significantly. James Clerk Maxwell's 1868 paper, 'On Governors,' provided the first rigorous mathematical analysis of the device, laying some of the groundwork for modern control theory. Later, figures like Edward Routh and Adolf Hurwitz further developed stability criteria for dynamic systems, building upon the practical foundation Watt had established.

Ethical & Societal Impact

The stability provided by the governor had ripple effects across society, profoundly shaping the modern world.

Transforming Labor and Production

By enabling consistent and predictable power, the governor facilitated the rise of the factory system. This had a profound impact on labor. Artisanal crafts gave way to mass production, and skilled manual labor was increasingly replaced by machine operators. While it led to unprecedented economic growth and the availability of goods, it also introduced new forms of work, often repetitive and demanding, and contributed to the social upheaval of urbanization and the formation of the industrial working class.

Economic Growth and Social Change

The ability to reliably power machinery on a large scale fueled an explosion in industrial output, driving economic growth and creating wealth, albeit unevenly distributed. It accelerated the shift from an agrarian to an industrial society, transforming demographics, urban landscapes, and social structures. The governor, by making steam power truly manageable, played a quiet but critical role in this vast societal transformation.

The Dawn of Automation Concerns

As one of the earliest widely adopted automatic machines, the governor implicitly raised questions about the role of human labor versus machine autonomy. While it didn't replace a vast workforce directly, it set a precedent for machines performing tasks previously requiring constant human vigilance. This was an early harbinger of the ongoing debates about automation, job displacement, and the evolving relationship between humans and technology.

Current Challenges

While the Watt governor itself is a historical artifact, its legacy presents ongoing challenges in understanding and education.

Historical Preservation and Understanding

Preserving and accurately interpreting historical industrial machinery like Watt's governor is crucial for understanding technological evolution. Many original examples are in museums, but the principles they embody often go unappreciated by the general public. Educating future generations about the fundamental importance of such 'simple' mechanisms in the history of science and engineering remains a challenge.

Relevance in Modern Control Theory Education

In an age of advanced digital control systems, microprocessors, and AI, demonstrating the foundational principles of feedback control using a purely mechanical device can be challenging yet incredibly illuminating. Integrating the historical context of the Watt governor into modern control theory curricula helps students grasp the fundamental, universal nature of these concepts, independent of their implementation technology.

Future Directions

Despite its age, the Watt governor continues to offer insights for future engineering and scientific endeavors.

Lessons for Autonomous Systems

The governor's robust, entirely mechanical self-regulation in the face of varying loads offers valuable lessons for designing resilient autonomous systems, especially those operating in environments where digital computation might be compromised or unavailable. Its simplicity and effectiveness highlight the power of well-designed physical systems for control.

Inspiration for Resilient Control Design

In an era increasingly concerned with the vulnerability of complex, digitally reliant systems, the elegance of the Watt governor as a self-contained, intrinsically stable mechanical controller serves as an inspiration. It encourages engineers to consider simpler, more robust analog or mechanical feedback loops where appropriate, adding layers of resilience to modern, often overly complex, control architectures.

Conclusion

James Watt's centrifugal governor, often relegated to a historical footnote, was far more than a mere adjunct to the steam engine; it was a conceptual leap, an 'algorithm' cast in iron and brass that brought stability to the chaotic heart of early industrial power. By demonstrating the immense power of automatic feedback control, it enabled the full realization of the steam engine's potential, thereby catalyzing the Industrial Revolution and laying the conceptual groundwork for almost all modern automation. This forgotten algorithm reminds us that some of the most profound technological advancements emerge not from complexity, but from the elegant application of fundamental principles to solve pressing practical problems, forever shaping our world.