The dawn of the Industrial Revolution was heralded by the roar and hiss of steam, a sound that would reshape economies, societies, and the very fabric of human existence. At the heart of this transformation was a Scottish instrument maker named James Watt, whose ingenious modifications to the primitive atmospheric engine not only dramatically improved its efficiency but also unlocked its potential to become the undisputed workhorse of a new industrial era.

Introduction to Industrial Revolution

The dawn of the Industrial Revolution was heralded not by a sudden flash of genius, but by a series of incremental, often painstaking, innovations. Among these, James Watt's profound improvements to the steam engine stand as a monumental achievement, fundamentally reshaping manufacturing, transportation, and society itself. What began as a mere ponderous machine for pumping water out of mines evolved, through Watt's thermodynamic insights, into the versatile, efficient powerhouse that fueled an era of unprecedented industrial growth.

Overview: The Imperative for Power

Before Watt, the dominant steam engine was Thomas Newcomen's atmospheric engine, first introduced in 1712. While revolutionary for its time, successfully pumping water from deep coal mines, the Newcomen engine was notoriously inefficient. Its operation relied on condensing steam directly within the main cylinder by injecting cold water, creating a vacuum that pulled the piston down. This cycle of heating and cooling the same cylinder with every stroke led to massive heat losses, making the engine a prodigious consumer of coal – a significant drawback even for a machine designed to extract coal. By the mid-18th century, as industrial ambitions grew, the limitations of the Newcomen engine became increasingly apparent, creating an urgent demand for a more economical and powerful prime mover. It was against this backdrop that James Watt, a Scottish instrument maker and engineer, began his fateful encounter with a Newcomen model in 1763.

Principles & Laws: The Science of Efficiency

Watt's genius lay in his intuitive grasp of heat transfer and the nascent field of thermodynamics. He recognized that the Newcomen engine's fundamental flaw was the cyclical heating and cooling of the cylinder. When cold water was injected to condense steam, it not only created a vacuum but also cooled the cylinder walls. On the subsequent stroke, a large quantity of incoming steam was immediately condensed on these cold walls, wasting a substantial amount of latent heat and delaying the buildup of effective steam pressure. This meant much more fuel was consumed to reheat the cylinder to working temperature for each cycle.

Watt's breakthrough was founded on a simple yet profound thermodynamic principle: for maximum efficiency, the cylinder should always be kept hot, while condensation should occur in a separate, perpetually cold vessel. This realization directly addressed the issue of latent heat, the energy required to change water into steam without changing its temperature. By condensing steam in a separate condenser, the main cylinder could remain hot (at steam temperature), minimizing heat loss and allowing steam to enter a pre-heated environment, thus greatly reducing fuel consumption. This was an early, practical application of principles that would later be formalized by scientists like Sadi Carnot.

Methods & Experiments: The Birth of the Separate Condenser

Watt's journey to invention began with meticulous observation and experimentation. Tasked with repairing a model Newcomen engine for the University of Glasgow, he became obsessed with its inefficiency. He measured the amount of steam consumed per stroke and noted the huge disparity between the theoretical and actual performance. Through these experiments, he deduced the vast quantities of heat wasted in reheating the cylinder.

His epiphany, famously occurring during a Sunday stroll in 1765, was the idea of the separate condenser. Instead of injecting cold water directly into the working cylinder, steam would be drawn from the cylinder into a separate, evacuated vessel kept cool by external water. This allowed the main cylinder to remain hot and ready for the next charge of steam. Initially, Watt experimented with various designs for the condenser, from surface condensers with metal plates to jet condensers where water was directly mixed with steam, settling on the latter for its effectiveness.

Beyond the separate condenser, Watt introduced several other critical improvements that collectively revolutionized the steam engine:

- Steam Jacket: Surrounding the main cylinder with a jacket of live steam, he ensured the cylinder walls remained at steam temperature, further reducing heat loss.

- Air Pump: To maintain the vacuum in the separate condenser and remove any non-condensable gases, Watt incorporated an air pump, driven by the engine itself.

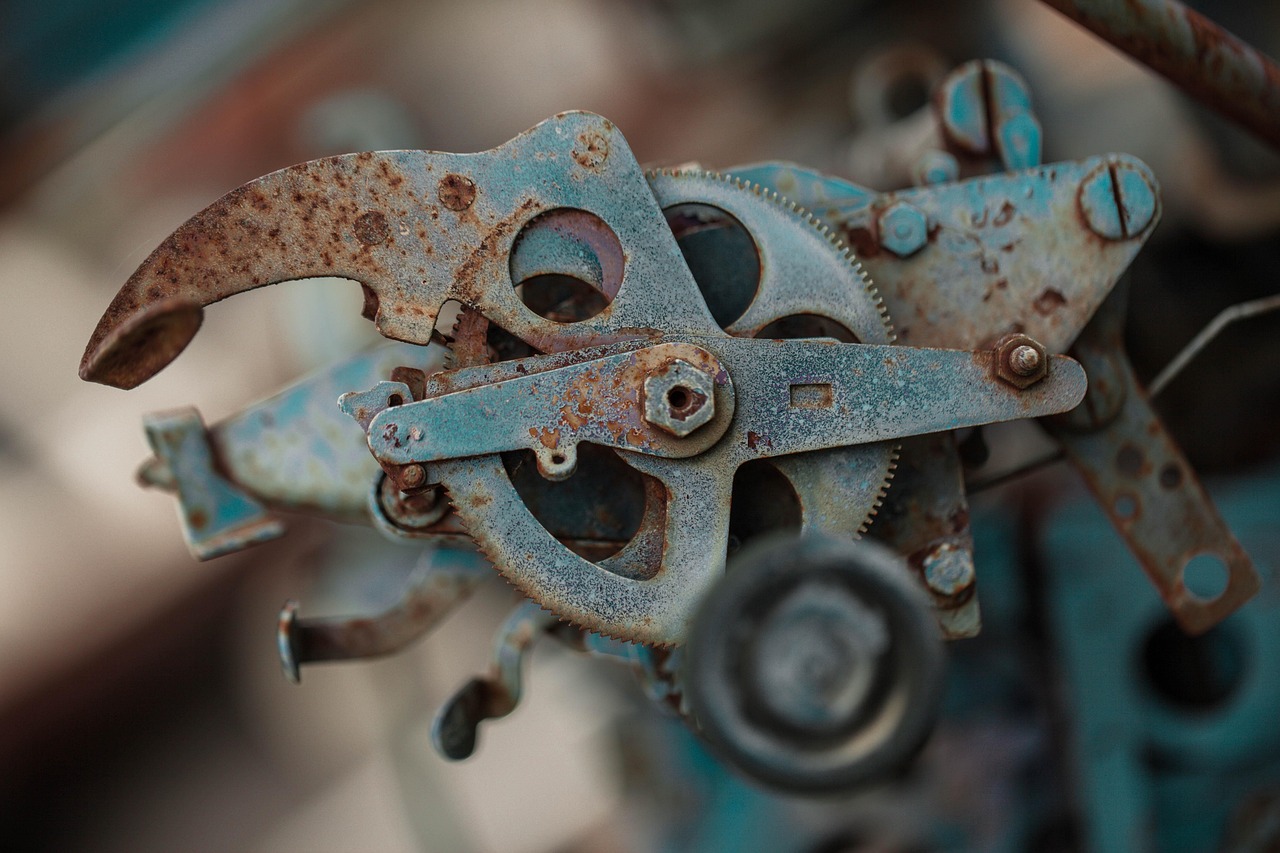

- Rotative Motion: The original Newcomen and early Watt engines were 'atmospheric' engines, producing an oscillating beam motion suitable for pumping. To drive machinery directly, Watt developed mechanisms for converting reciprocating motion into rotary motion. His initial patent for a crank mechanism was pirated, leading him to invent the ingenious 'sun and planet' gear in 1781, allowing factories to power their machinery directly.

- Double-Acting Engine: By sealing both ends of the cylinder and introducing steam alternately above and below the piston, Watt created a double-acting engine (1782) where steam pushed the piston in both directions, delivering continuous power and greatly increasing output.

- Parallel Motion Linkage: To guide the piston rod in a straight line without relying on heavy chains (which could only pull), Watt invented his famous parallel motion mechanism (1784), a masterpiece of mechanical engineering.

- Centrifugal Governor: For automatic speed control, Watt adapted and patented the centrifugal governor (1788), a feedback mechanism that regulated the steam supply to maintain a constant engine speed under varying loads. This innovation was crucial for stable factory operation.

Data & Results: Quantifying the Revolution

The impact of Watt's innovations was quantifiable and dramatic. The separate condenser alone reduced fuel consumption by approximately 75% compared to the Newcomen engine, a staggering improvement in efficiency. This meant that for the same amount of coal, a Watt engine could produce four times the work, or deliver the same work with a quarter of the fuel. The double-acting engine and rotative motion further amplified power output and versatility.

Economically, this translated into massive savings for mine owners and made the steam engine viable for a much wider range of industrial applications, particularly in areas where coal was not immediately available. The concept of 'horsepower,' a unit of power Watt himself coined and standardized, became a benchmark for engine performance and a testament to the new era of mechanical power.

Applications & Innovations: The Engine of Industry

The partnership between James Watt and the shrewd industrialist Matthew Boulton, formed in 1775, was crucial for commercializing Watt's inventions. Boulton provided the capital, manufacturing capacity (at the Soho Manufactory in Birmingham), and marketing prowess that Watt lacked. Together, Boulton & Watt became the premier suppliers of steam engines, initially focusing on pumping applications in Cornish tin and copper mines.

However, it was the development of the rotative engine that truly unlocked the potential of steam power for the broader Industrial Revolution. Watt's engines began to power:

- Textile Mills: Driving spinning jennies, water frames, and power looms, freeing mills from reliance on watercourses and allowing them to be built closer to labor and markets.

- Ironworks: Providing the blast for furnaces and powering forge hammers, dramatically increasing the production of iron, a foundational material for further industrial growth.

- Breweries & Distilleries: Pumping water and driving milling equipment.

- Water Supply Systems: Pumping clean water for nascent urban populations.

By the early 19th century, Boulton & Watt engines were recognized globally as the epitome of advanced engineering, symbolizing British industrial supremacy. While Watt himself remained cautious about high-pressure steam, his fundamental work laid the groundwork for future generations of engineers like Richard Trevithick and George Stephenson to develop high-pressure, lighter engines suitable for locomotives and steamboats, thus extending the revolution to transportation.

Key Figures: Minds Behind the Machines

- James Watt (1736–1819): The Scottish instrument maker whose profound understanding of heat led to the separate condenser, steam jacket, double-acting engine, parallel motion, and centrifugal governor, transforming the steam engine into a practical, efficient industrial workhorse.

- Matthew Boulton (1728–1809): The visionary English entrepreneur and manufacturer whose business acumen, financial backing, and manufacturing capabilities were instrumental in commercializing Watt's inventions and establishing Boulton & Watt as a dominant force in industrial engineering.

- Thomas Newcomen (1664–1729): The English inventor of the atmospheric engine, which, despite its inefficiencies, was the foundational steam technology that preceded and inspired Watt's improvements.

- John Smeaton (1724–1792): An eminent civil engineer of the era who conducted extensive analyses of Newcomen engines, providing quantitative data that likely influenced Watt's quest for efficiency.

Ethical & Societal Impact: A Double-Edged Sword

Watt's steam engine was undeniably a catalyst for unprecedented progress, but its impact was complex and often contradictory. The ready availability of mechanical power reshaped human society in profound ways:

- Urbanization and Factory System: Industries congregated around coalfields and transportation hubs, drawing populations from rural areas into burgeoning factory towns. This led to the rise of the factory system, characterized by specialized labor, mass production, and new forms of social organization.

- New Social Structures: The Industrial Revolution created a new industrial working class (proletariat) and a powerful class of industrialists and factory owners. This led to significant social stratification, labor unrest, and calls for reform.

- Environmental Impact: The widespread burning of coal to power steam engines dramatically increased air pollution in industrial centers, contributing to smog and respiratory illnesses. The demand for coal also drove extensive mining operations, with their own environmental and social costs.

- Global Power Shifts: Nations that embraced steam power gained immense economic and military advantages, contributing to colonialism and the expansion of global trade networks, often at the expense of less industrialized regions.

- Improved Living Standards: In the long term, the increased productivity and availability of goods led to a rise in general living standards for many, albeit often after decades of difficult adjustment and social struggle.

Future Directions: The Spirit of Innovation Endures

Watt's methodical approach to problem-solving and his relentless pursuit of efficiency continue to inspire. Future directions in energy and power generation often echo Watt's core insight:

- Advanced Materials: Development of materials that can withstand higher temperatures and pressures, or offer superior insulation, leading to more efficient heat engines (e.g., in gas turbines or advanced steam cycles).

- Smart Grids and AI: Utilizing artificial intelligence and machine learning to optimize energy distribution, predict demand, and manage complex energy systems with unprecedented efficiency, a direct evolution of Watt's governor regulating speed.

- Modular and Decentralized Power: Designing smaller, more efficient power units that can be deployed locally, reducing transmission losses and increasing resilience, much like Watt's engines brought power directly to factories.

- Beyond Combustion: Exploring new forms of energy conversion, such as fuel cells or nuclear fusion, which represent the ultimate quest for maximum energy extraction with minimal waste and environmental impact.

The spirit of questioning established norms and seeking fundamental improvements, exemplified by Watt's work, is the bedrock of future scientific and technological progress.

Conclusion: The Enduring Legacy

James Watt's thermodynamic breakthrough was far more than an engineering refinement; it was a conceptual leap that empowered the Industrial Revolution. By solving the critical problem of the Newcomen engine's inefficiency with his separate condenser and subsequent innovations, Watt transformed a localized mine pump into a universal prime mover. His engines became the mechanical heart of factories, propelling Britain, and subsequently the world, into an era of unprecedented industrial growth and technological advancement. The principles he intuitively grasped – minimizing heat loss, maximizing efficiency, and converting heat into useful work – laid the groundwork for modern thermodynamics and continue to guide our most ambitious energy projects. Watt's legacy is not just in the machines he built, but in the enduring scientific and engineering methodologies he pioneered, forever marking him as a titan of the Industrial Revolution and a fundamental shaper of the modern world.